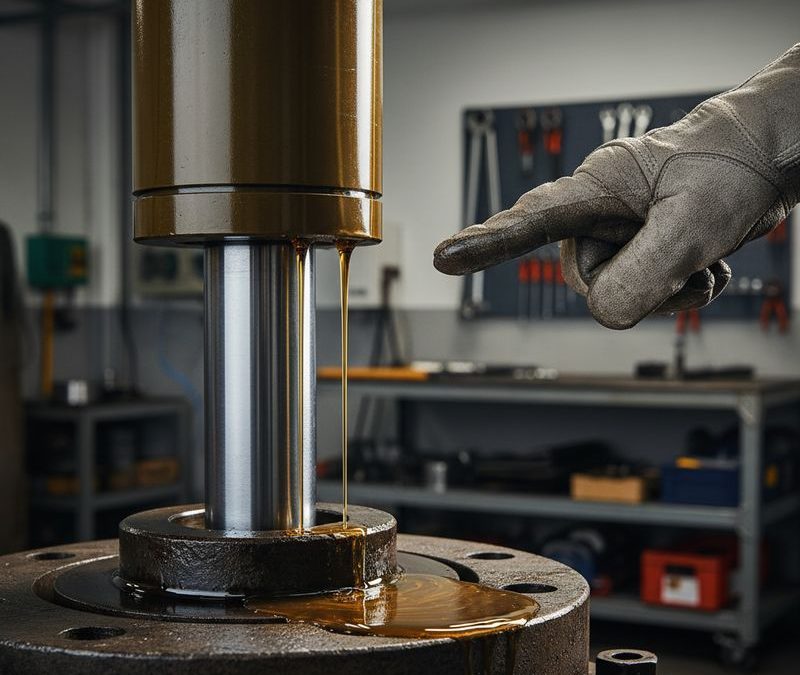

There’s nothing quite like the sight of a powerful machine, whether it’s on a farm, a construction site, or in a workshop, doing its job effortlessly. But when you spot that tell-tale sheen of oil, that unwelcome puddle forming beneath, you know a problem is brewing: a leaking hydraulic cylinder. It’s more than just an unsightly mess; it’s a sign of lost power, inefficiency, and potentially, a costly breakdown waiting to happen.

When faced with a hydraulic leak, the first thought for many might be, “Can I fix this myself?” It’s a natural reaction to want to save time and money. However, what often seems like a straightforward DIY project can quickly become a complicated, frustrating, and even dangerous ordeal. This guide isn’t just about identifying a leak; it’s about helping you make an informed decision on who to trust with the repair, often steering you towards the long-term benefits and peace of mind that come with professional expertise.

Working with hydraulic systems involves high pressures and specific procedures. Attempting a repair without the right knowledge, tools, or environment can be risky, leading to further damage, continued leaks, or even serious injury. Let’s explore why trusting a professional with your leaking hydraulic cylinder often proves to be the smartest, safest, and most cost-effective choice.

Signs Your Cylinder Is Leaking (And a Problem Is Brewing)

Before you even think about how to fix it, you need to be certain you have a leak. Hydraulic cylinder leaks often start small, but they rarely get better on their own. Keeping an eye out for these common signs can help you catch a problem early:

- Visible Oil Weeping or Dripping: This is the most obvious sign. You might see oil film on the cylinder rod, a slow drip, or even a noticeable puddle forming beneath the equipment when it’s idle or in use.

- Reduced Lifting Power or Sluggish Operation: If your equipment isn’t lifting as much as it used to, or if its movements are slow and jerky, a leak could be causing a loss of hydraulic pressure.

- Unusual Noises: Hissing or gurgling sounds from the hydraulic system can indicate air getting into the system due to a leak, or fluid bypassing seals internally.

- External Damage to the Cylinder Rod: Scratches, nicks, or pitting on the shiny surface of the cylinder rod can damage seals as the rod moves, leading to leaks.

- Excessive Heat: While not always directly linked to a leak, excessive heat in the hydraulic system can accelerate seal wear and contribute to future leaks.

If you notice any of these signs, it’s a clear indication that your hydraulic cylinder needs attention. Ignoring these warnings can lead to more severe damage, increasing repair costs and downtime.

The Reality of DIY Hydraulic Cylinder Repair

The internet is full of “how-to” guides, and while they can be tempting, tackling a hydraulic cylinder repair yourself comes with a unique set of challenges and potential pitfalls. It’s not just about getting your hands dirty; it’s about understanding a complex system.

1. The Right Tools Aren’t Always in Your Shed

Hydraulic cylinders aren’t designed to be opened with standard wrenches and screwdrivers. You’ll likely need specialized tools such as:

- Spanner wrenches: Often required to remove the gland nut (the part that holds the rod seal in place). These come in various sizes and shapes.

- Seal installation tools: Designed to prevent damage to delicate seals during installation. Trying to force a seal into place can easily tear or twist it, leading to an immediate re-leak.

- Honing tools: If the cylinder barrel is scored, a hone might be needed, which requires specific knowledge to use correctly.

- High-pressure safety equipment: Gauges, hoses, and proper fittings are crucial for safely depressurising the system.

Without these specialized tools, you risk damaging components, making the repair more expensive than if you’d gone to a professional in the first place.

2. Identifying the Root Cause Isn’t Always Obvious

A leak isn’t always just a worn-out seal. It’s a symptom, and simply replacing the seal might be a temporary fix if you don’t address the underlying problem. A professional technician can:

- Diagnose deeper issues: They can tell if a bent rod, a scored cylinder barrel, incorrect fluid, or internal bypass is causing the leak, not just the seal itself.

- Prevent recurrence: By fixing the true cause, they ensure the repair lasts, saving you the frustration of another leak shortly after your DIY attempt.

- Understand system dynamics: They know how all the components work together and how a problem in one area can affect another.

Guessing the cause can lead to repeat failures, wasted time, and more money spent on replacement parts.

3. The Risk of Contamination is High

Hydraulic systems are incredibly sensitive to contamination. Even a tiny piece of dirt or a stray fibre can cause significant damage to precision-engineered components and lead to premature seal failure.

- Cleanliness is critical:Professional hydraulic repair shops have dedicated, clean environments to dismantle and reassemble cylinders. They use filtered air and proper cleaning solutions.

- DIY environments are rarely sterile: Your garage or workshop, no matter how tidy, likely has dust, grime, and other contaminants that can easily get into an open hydraulic system.

- Consequences of contamination: Introducing contaminants during a repair can accelerate wear on new seals, scratch cylinder walls, and even damage the pump or valves in the wider hydraulic system, leading to far more expensive repairs down the line.

4. It’s Often More Than Just a Seal Replacement

What starts as a simple leak can unveil a host of other problems once the cylinder is disassembled. You might find:

These issues require specialized machining, welding, or parts replacement that are almost impossible to do correctly in a home workshop, making the professional route a necessity for a durable repair.

Why Trusting a Professional is the Smart Choice

Given the complexities and potential pitfalls of DIY repairs, choosing a professional for your leaking hydraulic cylinder often makes the most sense. Here’s why:

1. Expertise and Experience You Can Rely On

Professional hydraulic technicians have undergone extensive training and have years of hands-on experience. They:

- Accurately diagnose problems: They can quickly identify the root cause of a leak, often saving time and preventing misdiagnoses.

- Work efficiently: Their familiarity with various cylinder types and repair procedures means they can complete the job faster and more effectively.

- Stay updated: They are constantly learning about new technologies, materials, and repair techniques in the hydraulics industry.

2. Access to Proper Tools and Equipment

A dedicated hydraulic repair facility is equipped with all the specialized tools mentioned earlier, plus heavy-duty presses, testing benches, honing machines, and welding equipment. This means they can handle any repair, from a simple seal replacement to a complete cylinder rebuild, with precision and confidence. They can also source genuine, high-quality replacement parts, ensuring compatibility and durability.

3. Quality Workmanship and Guaranteed Results

When you pay for professional service, you’re paying for quality. Reputable repair shops stand by their work, often offering warranties on parts and labour. This gives you peace of mind, knowing that if an issue arises shortly after the repair, you’re covered. This contrasts sharply with DIY, where if something goes wrong, you’re back to square one, often out of pocket.

4. Significant Time and Money Savings (Really!)

While the initial cost of professional repair might seem higher than buying a seal kit, consider the true cost of DIY:

- Downtime:How much is your machinery costing you when it’s out of action? A professional can often get your equipment back up and running much faster.

- Repeated failures: If a DIY fix doesn’t address the root cause, you’ll be fixing it again soon, buying more parts, and spending more time.

- Further damage: An improper DIY repair can cause more extensive (and expensive) damage to the cylinder or other parts of the hydraulic system.

- Safety: Avoiding injury due to working with high-pressure systems is priceless.

A professional repair is an investment in the longevity and reliable performance of your equipment.

Frequently Asked Questions (FAQs) About Hydraulic Cylinder Leaks

We understand you’ll have questions. Here are some of the most common ones we hear:

How much does it cost to fix a leaking hydraulic cylinder in Australia?

The cost can vary significantly depending on the size of the cylinder, the extent of the damage (e.g., just seals, or a bent rod), and the labour rates of the repair shop. Minor resealing might be a few hundred dollars, while a full rebuild of a large industrial cylinder could run into thousands. It’s always best to get a detailed quote from a professional.

Is it cheaper to repair or replace a hydraulic cylinder?

This depends entirely on the damage. If the cylinder barrel is heavily scored, the rod is severely bent, or internal components are extensively worn, replacement might be the more cost-effective long-term solution. However, for most common leaks, repairing and resealing the existing cylinder is usually more economical, especially for custom or large cylinders. A professional assessment will give you the definitive answer.

How long does it take a professional to fix a hydraulic cylinder?

Again, this varies. A straightforward reseal could be completed in a few hours to a day, assuming parts are readily available. More complex repairs involving machining or special-order parts could take several days to a week. Mobile services can sometimes offer quicker on-site fixes for minor issues.

What are the common reasons a hydraulic cylinder leaks?

The most common reasons include:

- Worn seals: Natural wear and tear over time.

- Contamination: Dirt or debris in the hydraulic fluid damaging seals and surfaces.

- Physical damage: Scratches, nicks, or dents on the rod or barrel.

- Side loading: Excessive pressure on the rod from angles it’s not designed for.

- Improper fluid: Using the wrong type of hydraulic fluid can degrade seals.

- Over-pressurisation: System pressure exceeding the cylinder’s design limits.

Conclusion: Make the Smart Choice for Your Hydraulics

A leaking hydraulic cylinder is a problem that demands attention. While the temptation to “do it yourself” is understandable, the reality of hydraulic repair points overwhelmingly towards the benefits of professional intervention. From the specialized tools and expertise required to accurately diagnose and fix the root cause, to ensuring a contamination-free repair and providing lasting peace of mind, professional hydraulic technicians offer a value that’s hard to beat.

Don’t let a small leak turn into a major headache or an expensive catastrophe. If you’re dealing with a leaking hydraulic cylinder, take the smart step. Send us a message.